What impressed the Swiss company most about the new Tadano AC 7.450-1 was the 80-meter-long main boom in combination with the crane’s enormous lifting capacity. This is due not least to the new lateral Superlift SSL, which represents a decisive further development: The superlift arms are attached to the very front of the head, so that they are significantly longer and thus good for higher payloads – even some 8-axle trucks are left behind in a number of boom positions. EMIL EGGER AG sees another advantage in the Tadano Surround View camera system, which is unique on the market and graphically displays the maximum possible extension of the supports and the swing-through radius. As a result, Tadano Surround View greatly facilitates optimal positioning of the crane on the construction site. And on the road, the system helps to better detect pedestrians and cyclists when turning.

But the compact chassis and the associated good maneuverability under tight construction site conditions was also a decisive factor in the purchase decision. “Because of these advantages, we will mainly use the AC 7.450-1 for erecting construction cranes and for concrete and modular construction,” explains Michael Egger, who also emphasizes that he is following the merger of Tadano and Demag with great attention and sees the OneTadano project on a good track: “We own several cranes from both Lauf and Zweibrücken – including an AC 500-8 and an ATF 130. Therefore, we are very excited to see what we can expect from Tadano in the future.” For EMIL EGGER AG, this will in any case first be a Tadano AC 5.160-1, which the company has already ordered and which will be delivered in April 2022.

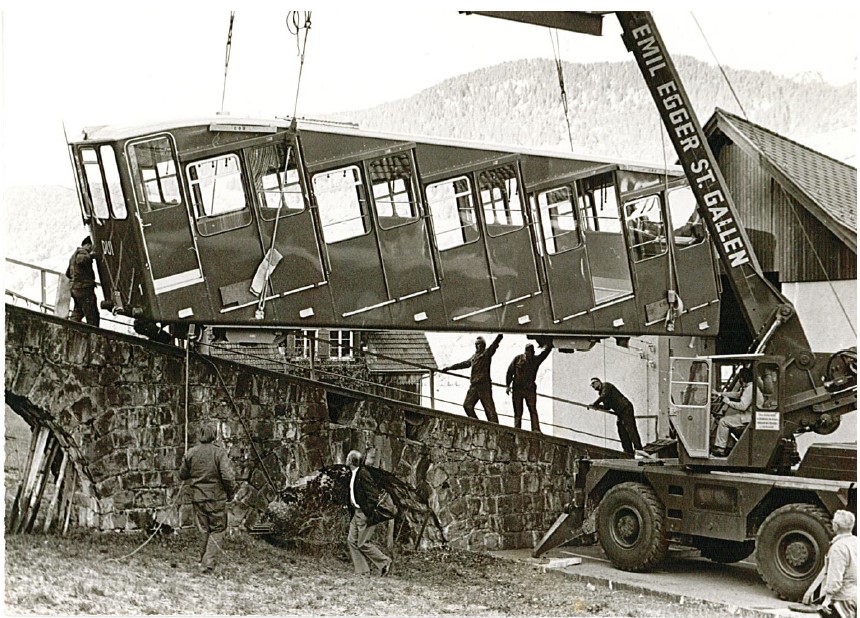

© Photo: Tadano

Professional Crane logistics

Fast, flexible and professional – that’s our motto. We can be reached 24 hours on the hotline +41 71 282 52 20 and are available in all regions of Switzerland. Thanks to our powerful crane and special transport sector, we are always ready for action. EMIL EGGER is also the only Swiss company to rank among the top 20 German-speaking crane service providers. Our diverse fleet includes mobile cranes, crawler cranes, mobile construction cranes, special cranes, truck cranes and mini cranes.