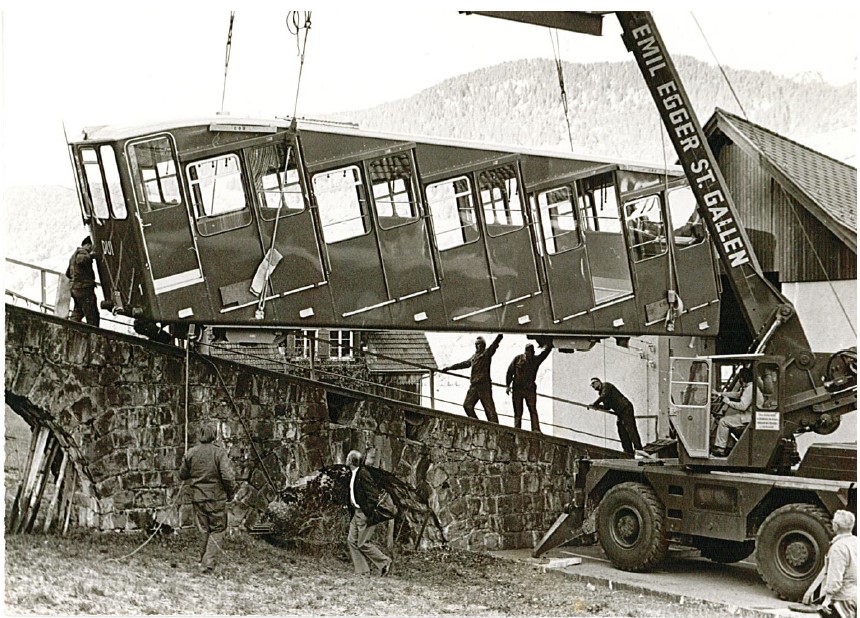

The six wind turbines were installed during the summer months on the Jura mountains in the canton of Vaud near the French border. EMIL EGGER AG relied on two powerful crawler cranes from Liebherr, the LR 1700-1.0 and the LR 11000. These powerful hoists proved their performance in a demanding terrain at an altitude of around 1,200 meters.

The challenges on this project were considerable, especially when lifting the generators, where the gross weight on the LR 11000, including hook block and slings, reached a whopping 71 tons. Here, a main mast of 114 meters was required to handle the impressive heights of around 100 meters. The rotors were somewhat lighter at 65 tons, but visually more spectacular. The 40-meter-long rotor blades were a special challenge for the experienced heavy transport professionals during delivery with special vehicles. On the ground, these were then assembled to the hub to complete wing stars, lifted and installed. Only by means of a special stop device could these huge components be swiveled into a vertical position during the lifting process.

The LR 1700-1.0 took on the erection of other wind turbines a few kilometers away, proving its high lifting height with a 99-meter main boom supplemented by a 12-meter tip.

Michael Egger, Chairman Business Manager of EMIL EGGER’s Heavy Lift Logistics Division, emphasized the importance of the cooperation with Liebherr for EMIL EGGER’s Heavy Lift Division:

“All crawler cranes in our fleet are from Liebherr. We rely entirely on the Liebherr brand for crawler crane technology because these modern machines are extremely practical and user-friendly. The machines are simply ‘state of the art’. And Liebherr’s service leaves little to be desired – and not just for reasons of proximity to the manufacturer. If we have a problem with our equipment, a mechanic is on site within two hours. This brings solutions within the shortest possible time and is highly appreciated by us and our customers.”